Armoured cable is a special cable that designed to give extra protection and reliability for wiring system. Generally armoured cable is used when cable may be subjected to harsh environment, or where there is risk of mechanical damage.This article explains the parts, construction, applications, and basic principles of armoured cables—in plain language.

What Is Armoured Cable?

An armoured cable is a type of electrical cable that includes a protective layer of armor, typically made from steel. This armor shields the internal conductors against mechanical damage, environmental hazards, and rodents, making these cables suitable for underground installations, industrial environments, and other demanding settings.

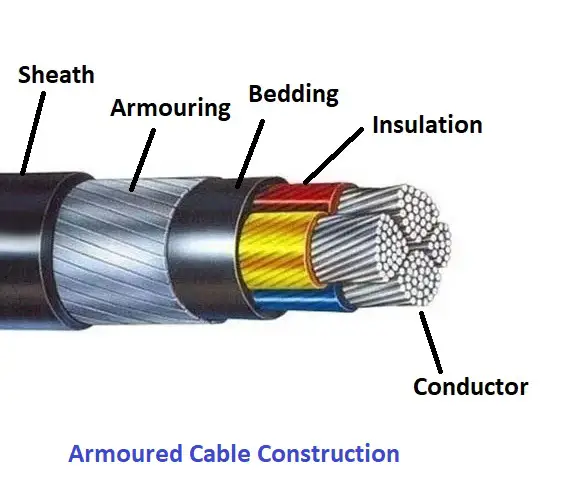

Parts of Armoured Cable

An armoured cable is made of different parts that serves some purpose to provide mechanical strength and electrical insulation to conductor.

- Conductor: conductor is a heart of cable that carry electricity. Typically it is made of aluminium or copper.

- Insulation: Around the conductor is an insulation layer. This is typically made from materials like cross-linked polyethylene (XLPE) or polyvinyl chloride (PVC). The role of insulation is to keep the conductor electrically separated from other materials so that electricity flows only where it should.

- Bedding (Inner Sheath): This is a protective barrier between the insulation and the armour. The bedding gives the cable extra support and helps prevent the insulation from interacting with the armour.

- Armour: The main protective layer. Armour is usually steel wire (SWA) or aluminum wire (AWA), but can also be made from steel tape or other metals. It defends against crushing, impact, rodents, and many environmental threats

- Sheath (Outer Sheath): The outermost layer, usually made from tough plastic like PVC or Low Smoke Zero Halogen (LSZH). It holds all the inner layers together and protects against weather, chemicals, and sunlight.

Types of Armoured Cable

There are several types of armoured cable, each designed for different tasks:

Steel Wire Armoured (SWA): Used in three-phase or multi-core cables where robust mechanical protection is needed, such as underground installation.

Aluminum Wire Armoured (AWA): Used in single-core cables, especially where cables may be exposed to magnetic fields, or where weight is a concern (like in tall buildings).

Steel Tape Armoured (STA): Offers protection mainly against crushing an

Applications of Armoured Cable

Armoured cables find wide use across various industries and environments because of their durability and reliable protection:

Underground Installations:Armoured cables are commonly used for underground electrical wiring in residential, commercial, and industrial settings. The armor protects the cables from mechanical damage caused by digging, soil pressure, and rodents.

Industrial Facilities:In factories and industrial plants, armoured cables are ideal because they protect wiring from physical impact, vibrations, chemicals, and extreme temperatures.

Power Distribution:In power generation and distribution, armoured cables transmit electricity safely and reliably over long distances and through harsh conditions.

Construction Sites:Temporary or permanent electrical installations at construction sites often use armoured cables due to their robustness and resistance to damage.

Hazardous Environments:Armoured cables are used in environments where there is a risk of explosion or fire, such as oil refineries and chemical plants, because their protective layers reduce the likelihood of electrical faults and sparks.

Marine and Offshore Installations:Specialized armoured cables are used in marine and offshore settings to resist corrosion, moisture, and mechanical stresses from waves and equipment.